Guitar Center's new CEO had a bad take about serious musicians and budget gear, but even the most inexpensive equipment often comes at a human price

In the May issue of Music Inc. magazine, Guitar Center CEO Gabe Dalporto — the new head of America's largest brick-and-mortar instrument retail chain — said the following regarding the store's new strategy:

[O]ver the years, we've evolved significantly into serving the beginner and entry-level customer — which is great — but if you walk through a GC store, you're going to see an awful lot of $300 guitars and $300 digital drum kits. [...] So if I'm a serious musician and I'm walking into a Guitar Center, it doesn't feel like the right place for me anymore.

Backlash was inevitable. Most notably, Tom Morello of Rage Against The Machine countered in a tweet that the band's Grammy-winning song "Tire Me" was recorded with a guitar bought for 40 mid-1990s Canadian dollars (about $55 USD today) from a Toronto pawn shop. The point was clear: Dalporto's comments seemed to convey elitism, and cheap guitars can be perfectly good instruments in their own right, even for "serious" musicians. Apart from being a little bit insulting to passionate and dedicated players who just don't have much money to throw around, Dalporto's implication is simply not accurate.

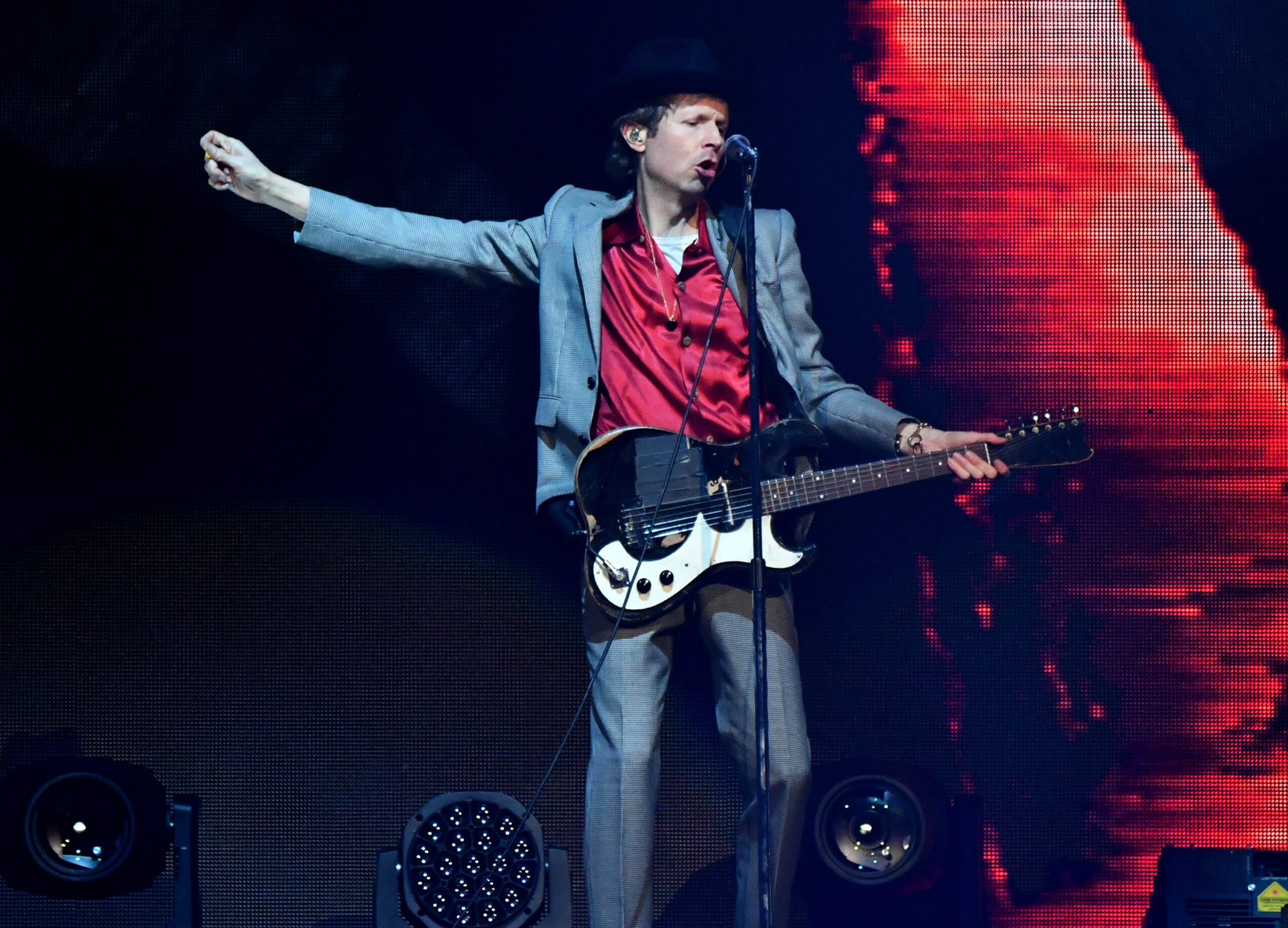

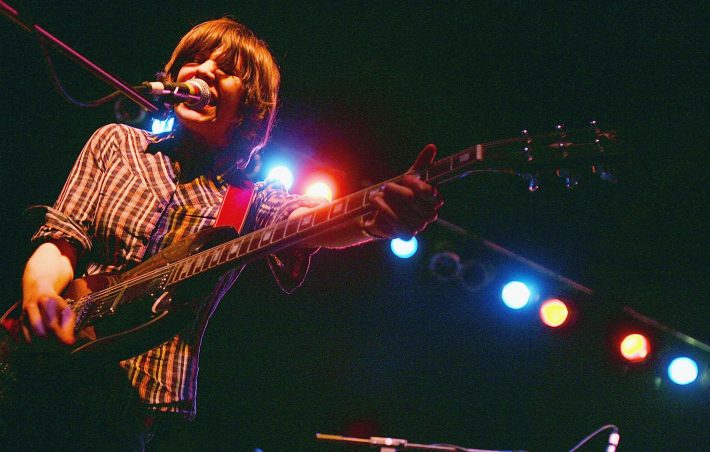

Many music legends started out with, or even still use, "budget" gear. Dolly Parton, born into poverty and evidently frugal to this day, played a bedazzled Mitchell MM100 (current price at Guitar Center: $140 USD) when she was inducted into the Rock And Roll Hall Of Fame two years ago. Mike Rutherford of Genesis, who can surely afford to play whatever he wants, played Squier Bullet Stratocasters costing as little as £100 on the band's last tour; he reportedly first bought them in COVID lockdown and grew to love them. Sleater-Kinney's Carrie Brownstein played an Epiphone G-310, a lower-priced version of the Gibson SG, for the first several years of the band's career; she doesn't play it anymore because it's on display at Seattle's Museum Of Pop Culture, alongside guitars belonging to Eric Clapton and Hank Williams, Sr.

To be fair to Dalporto, he didn't say Guitar Center would or should stop selling cheap guitars altogether; he would likely agree that these are what beginners, especially those with low family incomes, should reach for. The least expensive instrument available that isn't a complete piece of garbage is often the most logical thing for a parent to get for their kid when they start out; there's no sense in splurging on a top-of-the-line guitar or drum kit before it's known if a kid will even stick with it. (My own first guitar cost just $90 Canadian in 2003, $103 USD today, and seemingly half of my junior high peers that were learning to play owned the exact same Yamaha electric model that was being sold at Costco at the time). What irked people was Dalporto's condescending tone. It's true that those lucky enough to earn a living from their music — or just lucky enough to have money — will often move up to something on the higher end of things. But it's equally true that a cheaper instrument can look, sound, and feel pretty damn great in the right hands.

The conscious or simply unguarded use of cheap gear can undeniably be part of a musician's image or aesthetic. For some, playing an Epiphone Les Paul instead of a Gibson one can be a source of shame or embarrassment; for others, it can be a point of pride, as if to say, "I don't need a $2,000 guitar to sound good or look cool." My own favorite guitar to play is a Samick Malibu, a solidly built Indonesian-made Strat-type that cost $200 on Craigslist and didn't retail for much more when it was new; I'm in good company, because Parton likes them too. Zac Carper of FIDLAR takes it one step further, proudly playing a Strat copy from Costco decorated with a cheesy spiderweb graphic (and, to be fair, fitted with a replacement neck).

To boot, numerous lower-cost instruments from bygone eras also had eye-catching, even outlandish designs, sometimes looking like a Space Age cartoonist's rendering of what an alien rock star might play or the guitar equivalent of the generative AI program Midjourney giving people 50 teeth in their head and nine fingers on their left hand. In the '80s, '90s and early 2000s, Hanna-Barbera-looking instruments that were made of plywood or fiberglass and originally sold in department store catalogs (the mid-century equivalent of Amazon) could be picked up for cheap, and looked and sounded amazing in the hands of Jack White, St. Vincent, and Dan Auerbach. Ironically, and inevitably, boutique manufacturers have cashed in; the Toronto-based Eastwood company bought the rights to Montgomery Ward's "Airline" brand name 20-odd years ago and charges a premium for replicas of guitars that sold for what would now be less than $500.

Most experienced, non-snobbish players you're likely to meet will tell you that cheaper instruments may be more prone to quality control issues, but they are by no means automatically worse or undesirable, especially if one invests a modest amount of money in upgrades and maintenance. On cheaper guitars and basses, a common issue is sharp, protruding ends on the frets; an equally common fix is to (carefully) file them smooth. On electrics, hardware and pickups are other areas in which low-cost manufacturers might skimp; these, too, can be replaced for less than the added cost of a premium model, doubly so if the parts can be bought second-hand and one is reasonably handy with a screwdriver and soldering iron. Bargains are also abundant on the used gear market, and a previously owned instrument is more likely to have been "broken in" and received its share of TLC; one caveat, though, is that stuff from the pawn shop has a decent chance of having been stolen from a band's touring van three towns over.

Country music and the blues, two of the building blocks of rock, are based around guitars and other handheld string instruments, which are cheaper and easier to build and maintain than grand pianos. Modern popular music as we know it simply wouldn't exist without poor people having been able to get their hands on cheap but serviceable gear. Robert Johnson, debatably the single most influential musician of the 20th century, is said to have played a Gibson KG-14, which retailed in 1936 for $12.50; around $282 today. In the rock and roll era, for every player that saved up for a Fender Stratocaster, there were many others who ordered a much more affordable Silvertone from the Sears catalog.

In the early 1960s, demand for electric guitars exploded in Japan; this is largely attributed to surf pioneers the Ventures becoming one of the first Western rock bands to tour the country. Japanese manufacturers raced to perfect the art of modern luthiery, and soon guitars from brands like Yamaha and Ibanez became popular on both sides of the Pacific while North American companies struggled to meet demand on their own turf. It was around this time that American companies began outsourcing production to some of the same Japanese manufacturers.

Japan's propensity for technological innovation also helped; in the early 1970s, Japanese manufacturer Matsumoku — then responsible for many Ibanez, Yamaha, and Univox instruments — became one of the first guitar makers to use computer-controlled woodworking tools, commonly known as CNC machines, to automate away much of the difficulty of shaping bodies and necks and ramp up production even further. By the late 1970s and early 1980s, Japanese brands like Tokai, Fernandes, and Takamine were putting out guitars almost identical to — but cheaper than — those offered by Fender, Gibson and Martin; even the logos on the headstocks were suspiciously similar. Such instruments are often called "lawsuit guitars" because the similarities were close enough to prompt legal action.

A turning point came in 1982, when Fender, in the spirit of "if you can't beat 'em, join 'em", made deals with Japanese companies to produce official lower-cost Fender and Squier guitars. Meanwhile, Gibson had already moved production of almost all Epiphones from Michigan to the Matsumoku factory back in 1970; when that factory closed in 1987, production largely moved to South Korea to be handled by companies like Samick and Peerless. Since 2004, almost all Epiphones have been built at a Gibson-owned factory in Qingdao, China.

As great as it is to buy a new guitar for $300 or less, there may sometimes be human costs to the low price. Most guitars in the "budget" price range today are made in countries like China and Indonesia, where labor and manufacturing costs are significantly lower. There are several reasons for this, some of which are due to accidents of geography or lower costs of living, but ethical questions still understandably swirl regarding workplace safety, compensation, and even worker abuse. We've heard the stories about Nike sneakers being manufactured by South Asian children in fire traps and anti-suicide nets being installed at Foxconn electronics factories in China, but very little reliable information is available about the world's largest guitar makers.

One exception is Cor-Tek, a South Korea-based company best known for their own Cort brand of guitars and basses but also responsible for many offerings from Squier, Ibanez, Paul Reed Smith and G&L. According to a paper published by the Global Ethics Network in 2014, accusations of workplace abuse by Cor-Tek date back to 1988; alleged wrongdoings include laying off workers while falsely claiming financial hardship, forced overtime without extra pay, unsafe exposure to toxic chemicals and hazardous noise, and refusal to compensate workers for injuries sustained on the job. In particular, one worker's hands were said to require surgery after being injured by a wood grinder, and a female worker was said to have been driven by workplace abuse to commit suicide on factory grounds. In 1997, Cor-Tek began opening factories in China and Indonesia; workers said they were pressured to either quit or train new workers in these factories.

Workers at Cor-Tek factories in Incheon and Daejon formed a union in April of 2006. A year later on April 9, 2007, the Daejon factory was abruptly shut down, with non-union workers allegedly being compensated and reassured while union members were compensated less and pressured to resign; days later, everyone at the Incheon factory was laid off. On July 9 of that year, the closure of the Daejon plant was made permanent; on July 12, according to the Cort Action Network's timeline, a worker self-immolated in protest.

Between 2007 and 2009, Cort workers staged hunger strikes, occupations of electricity towers, and solidarity concerts with sympathetic musicians, while South Korean courts found Cor-Tek guilty of wrongful dismissal, health and safety violations, discriminatory hiring based on gender, and lying about financial difficulties. In January of 2010, demonstrations were held at the National Association of Music Merchants (NAMM) trade show in Anaheim, California; vocally left-wing musicians like Tom Morello, Boots Riley of the Coup, System Of A Down's Serj Tankian, and Wayne Kramer of the MC5 offered their support.

The South Korean Supreme Court ruled in 2012 that, while the initial layoffs were unjustified, the ultimate closure of the factories later in the year were not, and thus none of the workers could get their jobs back; this decision was upheld in June of 2014. Protests didn't completely cease, though, and on April 22, 2019, after a 42-day hunger strike, three former employees finally reached an agreement with Cor-Tek: the three men would receive "honorary reinstatement", 25 members of the Cort union (including them) would receive a financial settlement, all lawsuits would be withdrawn, and the company would publicly express its regret for the layoffs. As reported by Hankyoreh, it had been the longest labor dispute in South Korean history to date: 13 years from the formation of the union.

Guitar Center's main competitor in the US, Sam Ash, announced this April that it was going out of business; Guitar Center might not even need Dalporto's new strategy to up its sales, now that it's one of the only nationwide brick-and-mortar chains still standing. Swift competition still exists, however, in e-commerce: Sweetwater is America's largest dedicated online music gear retailer, and web-based behemoths like Amazon and Wish are now selling a wide variety of inexpensive gear in addition to every other conceivable product on Earth. Amazon has even sold small guitar effects pedals under its Amazon Basics brand, alongside everyday items like batteries and cutlery.

Again, ethical concerns abound regarding the business practices of e-commerce giants: Amazon's treatment of workers, alleged union busting, and apparent desire for monopoly are well-known at this point. More generally, all of these platforms use "drop shipping," with the platform merely acting as a middleman between the consumer and the supplier who actually fulfills the order. As such, the platforms have little ability or incentive to guarantee the quality of the product or the ethics of the supplier; Wish.com has a code of conduct prohibiting merchants from using unfair labor practices, but how well these policies are actually enforced is unclear.

For most people, the mere fact that a product is made in a foreign country is not the issue; the real ethical concern is that the workers involved might be treated poorly or paid too little, not to mention the potential environmental costs of constantly shipping things overseas. It's cliché nowadays to mock those who are vocal about issues of consumer ethics yet continue to buy cheap foreign-made goods through corporate retailers; it's only slightly less cliché to counter that there's no ethical consumption under late capitalism.

Regardless, the truth is that cheaply made foreign products in general — guitars included — are ubiquitous. Musicians and aspiring players who legitimately can't afford most domestically made instruments have little choice when it comes to buying new (or even second-hand, much of the time) if they want to avoid products whose labor pedigree is unclear. Pickings are slim, but options do exist: Godin, a Quebec-based manufacturer, makes several good-quality models of acoustic guitar under several brand names that retail in Canada for as little as $450 CAD ($330 USD). However, none of their solid-body electrics currently retail for less than $1,000 CAD, and even the Art & Lutherie brand has begun to introduce Chinese-made models that sell for $400 CAD.

For those unable or unwilling to indulge in consumerism of any kind, there exist other avenues to obtaining gear. Even the public sector is getting involved: many public library systems across North America — including those of Brooklyn, Philadelphia, Toronto, Ann Arbor, Calgary, and Sacramento — operate instrument libraries, which allow those with library cards to check out things like guitars and trombones as well as books. The city of Burnaby, British Columbia (adjacent to Vancouver) even directly operates its own such program, Harmony For All, which loans instruments to citizens for up to one year at a time completely free of charge and also provides financial assistance to cash-strapped youth wishing to take music lessons. The program was started by Burnaby city councilor Joe Keithley, better known worldwide as D.O.A. frontman and punk rock legend Joey Shithead. (Full disclosure: I've directed an official D.O.A. music video).

It's not just instruments, in the traditional sense, for which affordability matters when it comes to music accessibility. Electronic devices like synthesizers, samplers, sequencers, and home recorders have been increasingly integral to the production of music for several decades as the price tags shrink with the circuit boards. What's often now a compact and affordable hunk of plastic and metal, or even just a piece of software, was once a bulky device costing many thousands of dollars. It's worth noting that some of the aforementioned instrument-lending programs loan out not just guitars and drums, but also synths, sequencers, mixers and even lighting rigs.

It's often said that the looting which occurred during the New York City blackout of 1977 was the way many inner-city youths in the Bronx were able to obtain the turntables, mixers and PAs they used to further develop the burgeoning genre of hip-hop. Some dismiss the story as an apocryphal oversimplification, given that it's mostly based on the testimony of just two DJs, but it remains true that yet another dominant genre of modern popular music was birthed by working-class people making use of increasingly affordable technology in whatever ways they could. (Then again, would you be willing to admit on the record that you began your career using stolen goods?)

The demand for inexpensive gear is unlikely to recede, giving the industry little incentive to not seek the cheapest labor possible. Besides the Cor-Tek saga, a full exposé of the cheap foreign gear industry is yet to appear, and the idea that there was just one bad apple in Korea seems too good to be true. I found a single article from 2013 about the possible closure of a Yamaha-owned factory in Indonesia as an alleged union-busting tactic, but no articles about what came of it.

It's folly, though, to single out overseas territories while ignoring subpar working conditions at home; domestic companies can have spotty records of their own. Gibson closed up shop in its native Kalamazoo in 1985 after factory workers unionized and set up a non-union factory in Nashville, where workers were almost forced to keep working as COVID lockdowns were picking up speed in March of 2020. There's no hard, direct evidence as of yet that anything bought from Temu is made with forced labor in Xinjiang, but it may be that the Amazon driver who delivered you gummy bears last week has had to pee in a bottle to stay on schedule.

If we're going to keep buying them, we should demand transparency regarding the labor practices of not just the companies supplying us with new $300 guitars, but also the domestic manufacturers selling their wares to us for thousands. Alternatively, your local library may be able to provide you with an instrument along with the book that tells you how to play it; I myself have always wanted to learn the saxophone.

Stereogum is an independent, reader-supported publication. Become a VIP Member to view this site without ads and get exclusive content.